DelphySkin Ltd SOHO ST. JULIAN'SPunchbowl Centre, Elia Zammit Street,STJ 3154 ST. JULIANS Malta info(at)Delftex.com

Studies

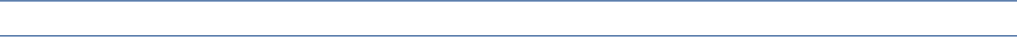

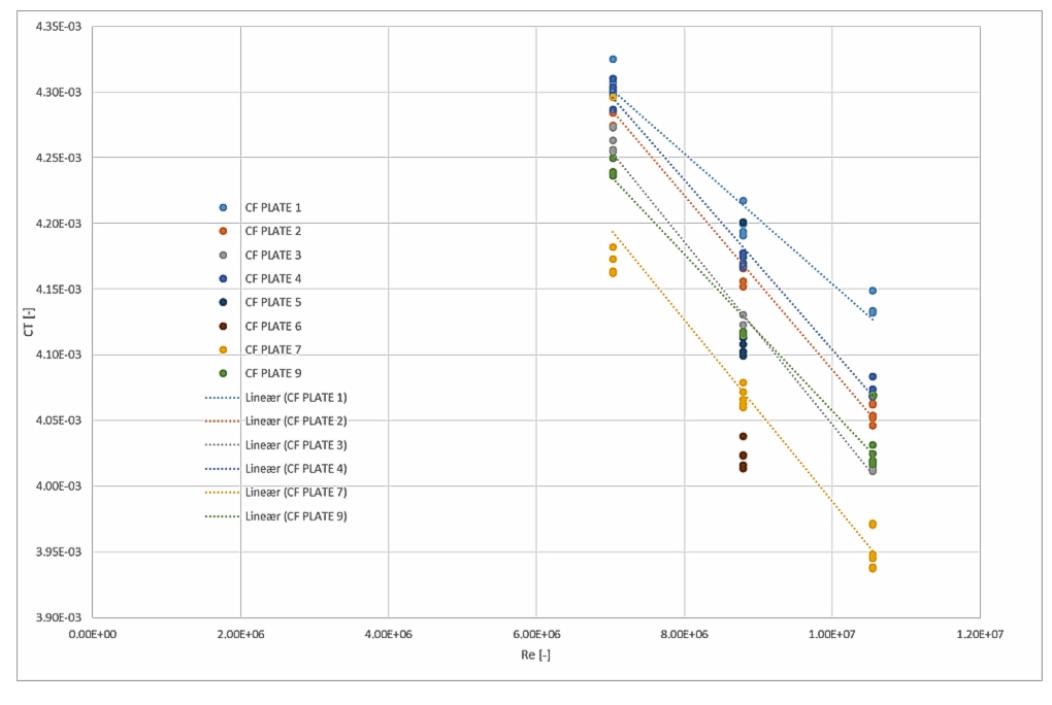

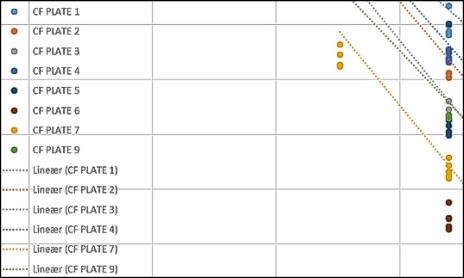

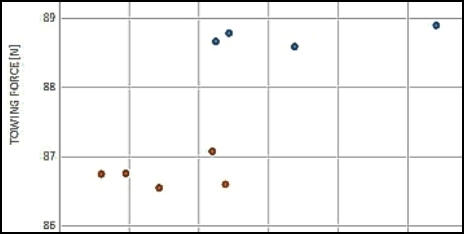

Marintek

in Norway is specialised on testing water vehicles. In April 2016 they compared 9 paintings. Our paint was Seajet 012 Universal Primer in version A (original) plate 5 and B plate 6 changed with our Delftex® technology. The compare at 5m/s water speed shows the lower towing force (~87 N down to ~85 N) .

Compare to all other paints

our plate 5 and plate 6 (DELPHYSKIN®) was compared at 5 m/s to 7 other. In the middle row of the graph you can see that plate 6 (brown dots) has the lowest friction of all paintings.

2.3%

less

friction

Delphyskin® PAINT

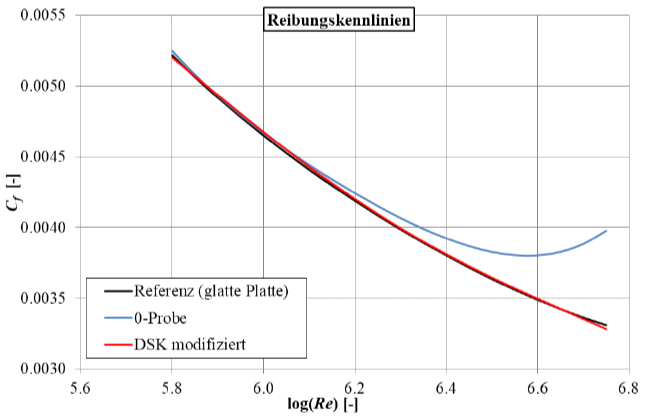

Test results SVA Potsdam

A boat paint (original vs. DelphySkin® modified) was tested for the reduction

the frictional resistance in the water flow channel

On the basis of the test results, the reduction in resistance and

Fuel savings determined:

- Sliding boat

resistance reduction and fuel saving of 2.5%.

- Tanker

Resistance reduction and fuel saving of 7.8%

- Aircraft*

Reduced drag and fuel savings of 1.1 % (if 60% of the

surface are painted with the DSK-modified paint)

* extrapolation to the medium air (boat paint)

Ultrasonic test procedure on liquid DelphySkin® -

treated paint

left is the fingerprint of the treated DelphySkin® paint

Another measurement with a clear coat

SVA

has

a

friction

tunnel

(see

the

picture

below).

In

the

test

section

of

this

facility

(the

black

part

in

the

picture)

two

flat

and

1.2

m

long

panels

are

installed

so

that

these

form

a

narrow

rectangular

channel.

The

panels

are

coated

with

the

coating

o

to

be

investigated

(with

or

without

DephySkin®).

The

tunnel

is

traversed

by

water

with

a

speed

of

1

to

17

m/s

in

19

steps.

By

the

simultaneous

measurement

of

the

flow

rate

and

the

pressure

loss

measured

at

12

positions

along

the

test

section,

the

wall

shear

stress

can

be

detected

and

finally

the

frictional

resistance

coefficient

of

the

surface

is

calculated.

The

test

procedure

for

one

pair

of

plate

includes

1

h

conditioning

of

the

test

facility

and

2.5

h

measuring

of

one

coating.

Each

measurement

consists

of

3

runs

that

are

averaged.

The

results

are

plotted

as

friction

resistance

coefficients

in

dependency

of

the

Reynolds

number,

which

is

an

equivalent

expression

for

the

flow

speed.

Measurements

with

reference

plates

(smooth

stainless

steel) at the beginning and the end of the measurement campaign help to classify the results.

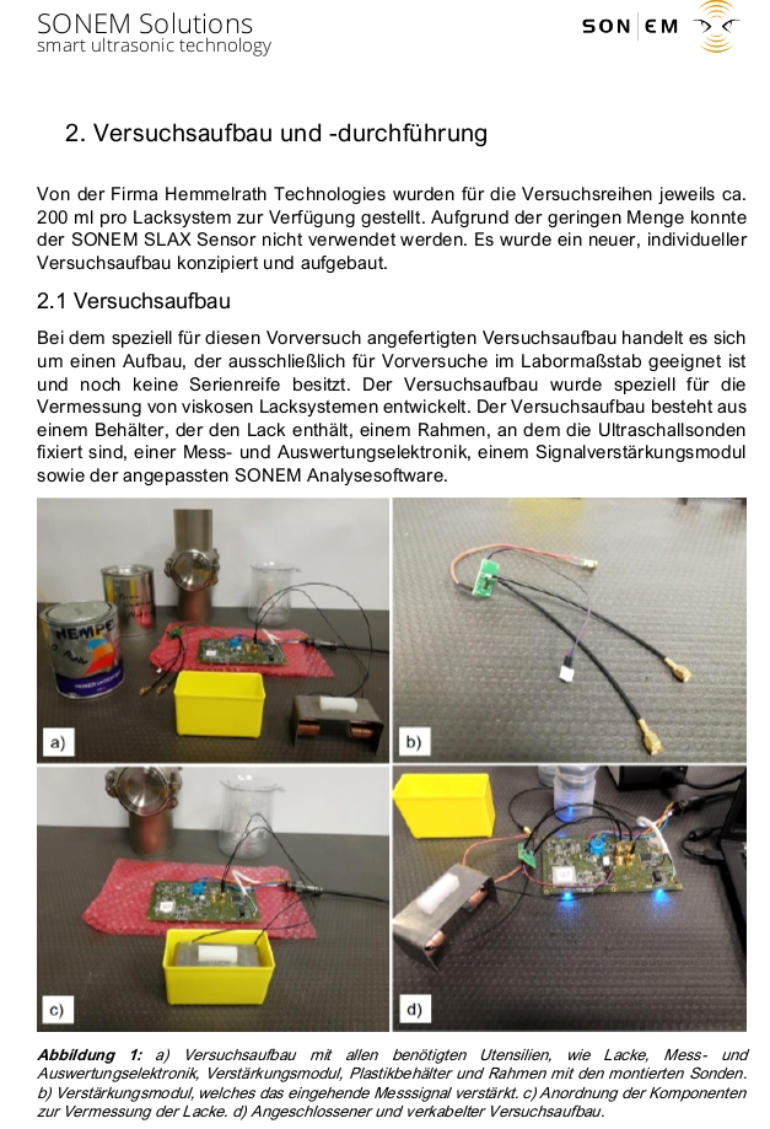

Experimental setup and execution

The

test

series

were

made

available

by

Hemmelrath

Technologies,

approx.200ml

per

paint

system.

Due

to

the

small

quantity,

the

SONEM

SLAX

sensor

could

not

be

used.

A

new,

individual

test

setup

was designed and built.

The experimental setup

The

test

setup

specially

made

for

this

preliminary

test

is

a

setup

that

is

only

suitable

for

preliminary

tests

on

a

laboratory

scale

and

is

not

yet

ready

for

series

production.

The

test

setup

was

specially

developed

for

measuring

viscous

paint

systems.

The

experimental

setup

consists

of

a

container

containing

the

paint,

a

frame

to

which

the

ultrasonic

probes

are

fixed,

measurement

and

evaluation

electronics,

a

signal

amplification

module

and

the

adapted SONEM analysis

software

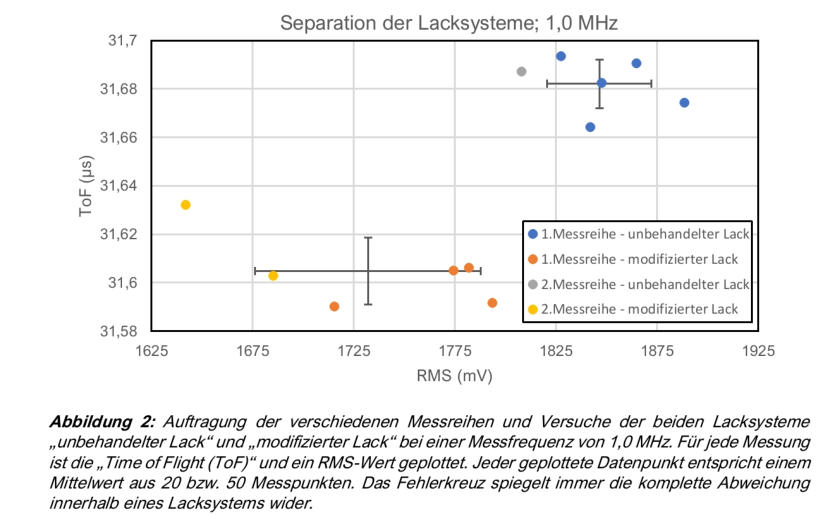

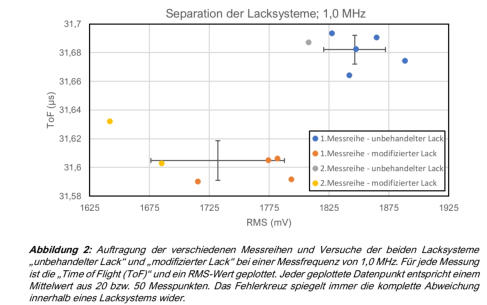

Application

of

the

various

series

of

measurements

and

tests

of

the

two

paint

systems

"untreated

paint"

and

"DSK

modified

paint"

at

a

measuring

frequency

of

1.0

MHz.For

each

measurement

the

"TIME

OF

FLIGHT

(TOF)"

and

an

RMS

value

are

plotted.Each

plotted

data

point

corresponds

to

an

average

of

20

or

50

measurement

points.

The

error

cross always reflects the complete deviation within a paint system.

SONEM

develops

and

builds

ultrasonic

sensors

for

the

process

industry.

Our

technology

is

in

contrast

to

classic

imaging

ultrasonic

technology,

not

based

on

interdependencies

of

ultrasonic

waves

and

surfaces.

Moreover

we

harness

molecular

acoustics

of

mediums

to

gather

information.

Molecular

acoustics

expresses

the wavelike, substance-specific expansion of the ultrasonic signal throughout the medium. Learn more now!

Based

on

the

received

ultraonic

signal,

we

create

a

detailed

dataset

of

the

medium,

the

so

called

SONEM

Fingerprint.

By

ultilizing

statistical

algorithms,

conclusions

can

be

drawn

about

mutiple

medium

attributes.

All relevant information can be accessed and further processed via the SONEM cloud.

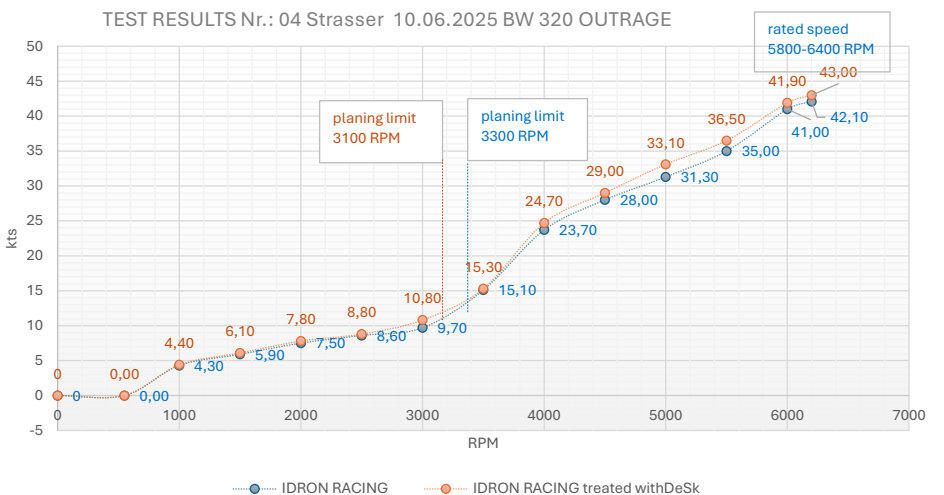

Summary of the test result: 10/06/2025 in TRIEST – Baia di Trieste

Each test run was repeated 3 times, and the average was recorded.

Bosto

n

Whal

e

r

,

320

O

u

t

rage,

W

eig

ht

(i

n

c

l

udi

n

g e

n

gi

n

es)

4

430

k

g

,

E

n

g

ine:

2

x

V

e

rado

275

C

XX

L,

202

kW (

275

hp)

Le

ngth 10

.

80

m

W

id

th

3.

09

m

D

e

pt

h 0

.

55

m

Me

a

su

r

ed

b

y GPS,

thr

ee

p

eo

pl

e o

n

b

oa

r

d,

600

l

o

f

f

ue

l

, sh

all

ow w

a

ter, no

wind (

2

kts), sm

all

const

a

nt oce

a

n

current in t

h

e s

a

me di

r

ec

t

io

n

.

1

.

Tes

t

09

:

00

S

h

o

rt

su

rf

ace g

r

i

n

di

n

g,

n

ew

p

ai

nt

ed spr

ay

ed with

M

icron

350

2

.

Tes

t

14

:

00

S

h

o

rt

su

rf

ace g

r

i

n

di

n

g,

p

ai

nt

ed o

v

er spr

ay

ed with

M

icron

350

tre

a

ted with De

l

ph

y

Skin®

Without DelphySkin®

Cruising speed 10 min by 25 kts need 4500 RPM consumption 66, 8 l/h (2 engines together)

With DelphySkin®

Cruising speed 10 min by 25 kts need 4050 RPM consumption 55, 1 l/h (2 engines together)

17% less fuel

consumption at

25 kts

© N-G

Studies

Marintek

in Norway is specialised on testing water vehicles. In April 2016 they compared 9 paintings. Our paint was Seajet 012 Universal Primer in version A (original) plate 5 and B plate 6 changed with our Delftex® technology. The compare at 5m/s water speed shows the lower towing force (~87 N down to ~85 N) .Compare to all other paints

our plate 5 and plate 6 (DELPHYSKIN®) was compared at 5 m/s to 7 other. In the middle row of the graph you can see that plate 6 (brown dots) has the lowest friction of all paintings.

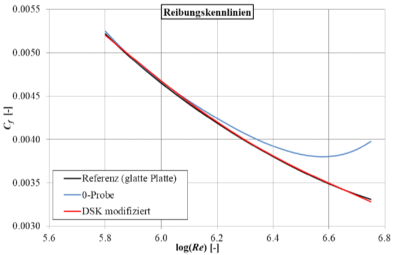

Test results SVA Potsdam

A boat paint (original vs. DelphySkin® modified) was tested for the reduction

the frictional resistance in the water flow channel

On the basis of the test results, the reduction in resistance and

Fuel savings determined:

- Sliding boat

resistance reduction and fuel saving of 2.5%.

- Tanker

Resistance reduction and fuel saving of 7.8 %

- Aircraft*

Reduced drag and fuel savings of 1.1 % (if 60% of the

surface are painted with the DSK-modified paint)

* extrapolation to the medium air (boat paint)

Ultrasonic test procedure on liquid DelphySkin® -

treated paint

SONEM develops and builds ultrasonic sensors for the process industry. Our

technology is in contrast to classic imaging ultrasonic technology, not based on

interdependencies of ultrasonic waves and surfaces. Moreover we harness

molecular acoustics of mediums to gather information. Molecular acoustics

expresses the wavelike, substance-specific expansion of the ultrasonic signal

throughout the medium. Learn more now!

Based on the received ultraonic signal, we create a detailed dataset of the medium,

the so called SONEM Fingerprint. By ultilizing statistical algorithms, conclusions can

be drawn about mutiple medium attributes. All relevant information can be accessed

and further processed via the SONEM cloud.

left is the fingerprint of the treated DelphySkin® paint

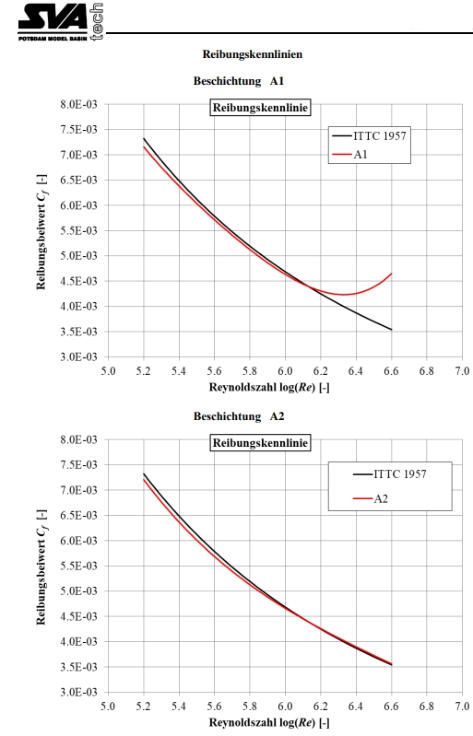

SVA

has

a

friction

tunnel

(see

the

picture

below).

In

the

test

section

of

this

facility

(the

black

part

in

the

picture)

two

flat

and

1.2

m

long

panels

are

installed

so

that

these

form

a

narrow

rectangular

channel.

The

panels

are

coated

with

the

coating

o

to

be

investigated

(with

or

without

DephySkin®).

The

tunnel

is

traversed

by

water

with

a

speed

of

1

to

17

m/s

in

19

steps.

By

the

simultaneous

measurement

of

the

flow

rate

and

the

pressure

loss

measured

at

12

positions

along

the

test

section,

the

wall

shear

stress

can

be

detected

and

finally

the

frictional

resistance

coefficient

of

the

surface

is

calculated.

The

test

procedure

for

one

pair

of

plate

includes

1

h

conditioning

of

the

test

facility

and

2.5

h

measuring

of

one

coating.

Each

measurement

consists

of

3

runs

that

are

averaged.

The

results

are

plotted

as

friction

resistance

coefficients

in

dependency

of

the

Reynolds

number,

which

is

an

equivalent

expression

for

the

flow

speed.

Measurements

with

reference

plates

(smooth

stainless

steel)

at

the

beginning

and

the

end

of the measurement campaign help to classify the results.